Rumaila has several wells that produce more than 400,000 barrels per day (bpd), which are supported by Electrical Submersible Pumps (ESPs); it’s the job of the ESP Troubleshooting Team to make sure that these wells continue to produce to their maximum capability. In practice, this means my colleagues and I monitor the wells by collecting and analyzing data that can detect possible problems and supervise subsequent troubleshooting jobs. It is important we restore any tripped ESP wells as soon as possible to avoid loss in production time.

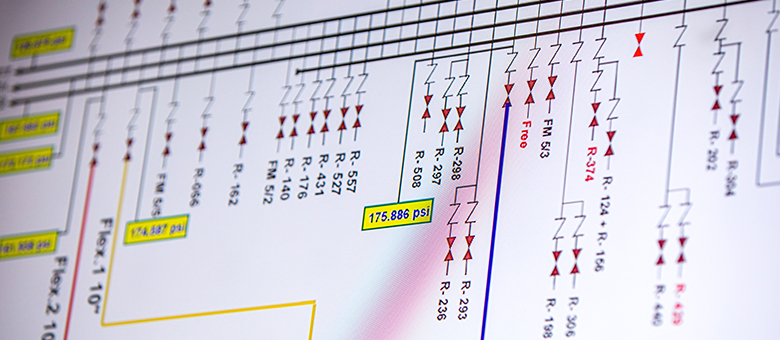

Once an anomaly in the data has been flagged, we must work diligently and swiftly to identify the source of the problem. This isn’t always easy! A recent example of this was the well R-463 flowline. Despite appearing to function normally, it was showing unusually high-pressure readings – almost double the expected level – which was a cause for concern. As everything else appeared normal, my worry was that a partial blocking had occurred somewhere in the flow path and was causing this escalating pressure. We had to act promptly to avoid potential overheating of the ESP motor, which could have resulted in an ESP electric downhole failure.

We discovered that the downhole sensor had ceased to function, but the partial blockage was causing fluctuations in readings, and although the flowline Pressure Transmitter seemed to be working normally, we found it was capturing inaccurate readings.

Once we’d identified the problem, we shared the information with the Troubleshooting Team Lead and relevant managers, so that we could request an immediate shutdown of well R-463 to tackle the cause behind the high pressure. With the help of the Instrumentations Team we were able to restart the well after only a few hours.

Had we not undertaken this investigation, the ESP would most likely have failed, causing several weeks of lost production as well as a costly workover job of extracting and replacing the ESP.

I have been at Rumaila three years now and am proud to be part of the ESP Troubleshooting Team; we always respond swiftly to issues with effective solutions. It is rewarding to know that my work helps towards keeping the oilfield running efficiently with a high production rate.